Centrifuge for salt

Our centrifuge offers precise liquid-solid separation, allowing for further washing and purification of crystals while also reducing the humidity of the salt. This innovative design combines continuous process capabilities with minimal maintenance needs.

How to Separate Salt

Typically, salt separation is achieved using HR Pusher centrifuge or LWL Horizontal screen worm centrifuge, both of which are highly effective.

Solid content

The LWL series Horizontal screen worm centrifuge has the ability to process solid materials with a range of 20% – 80%, while HR Pusher centrifuges cannot handle this range and are limited to around 30% – 70%.

Capacity

Choose the HR Pusher centrifuge single machine production if the solid content is not too high, the production demand is limited, and there is a budget constraint. This is because the inflow flow will be faster and result in a smaller difference between HR and LWL Salt Separation, making it a more efficient option.

Moisture

The merchant suggests that both Salt Separation options have a similar range of 5%-7%.

Particle

This product provides customers with assistance in selecting screen mesh according to the desired particle size.

The particle size of the LWL series Horizontal screen worm centrifuge is under 200 mesh, while the HR Pusher centrifuge has a particle size under 250 mesh.

The Siphonic Centrifuge is a fully automated centrifuge that can operate continuously or in batches, depending on its structure. It is available in two types: the Siphonic Scraper Centrifuge (GKH series) and the common scraper centrifuge (GK series).

This centrifuge can operate in both automatic and manual modes for periodic feeding, dehydration, washing, and discharging of material.

The sophonic scraper centrifuge boasts a siphonic force equivalent to vacuum, making it more efficient in production and separation compared to standard scraper centrifuges. This feature is particularly advantageous for materials with low solids content, high viscosity, slow filtration, and the need for filter cake washing.

The GK Peeler centrifuge is a solid-liquid separation equipment that uses continuous operation and intermittent discharge. It is controlled by a programmable logic controller and utilizes a frequency converter for speed regulation, with a braking system that includes dynamic braking and regenerative braking. Through various programs such as product level detection, speed detection, and shaft temperature and vibration monitoring, the entire separation process can be automatically cycled, including feeding, dehydration, washing, and discharge.

The GKH Horizontal Peeler Siphon Centrifuge utilizes both centrifugal force and siphon power to achieve separation, resulting in a 50% increase in production capacity and reduced moisture content in the residues. The design of the drum allows for efficient removal of clear liquid through a liquid pipe without any materials being deposited. This makes it well-suited for separating subtle materials that are normally difficult to separate. The siphon centrifuge is particularly useful in the fields of medicine, food, environmental protection, and chemistry due to its unique features.

Horizontal Peeler features and configurations.

- Safety protection.

- Action elements with automated control.

- PLC control, easy maintenance and operation.

- Strongly designed structure for a welded machine case.

- Independent hydraulic station can be installed separately, convenient to repair.

- All seals are made of the fluorous rubber and silicon rubber.

- The liquid damping vibration absorber has the option for additional instructions, which can help effectively absorb vibrations and maintain stable operation.

- Stable start-up and simple control, effectively protecting the motor from overload-related damage. Optional inverter start-up for variable speed control.

- Two discharging modes available.

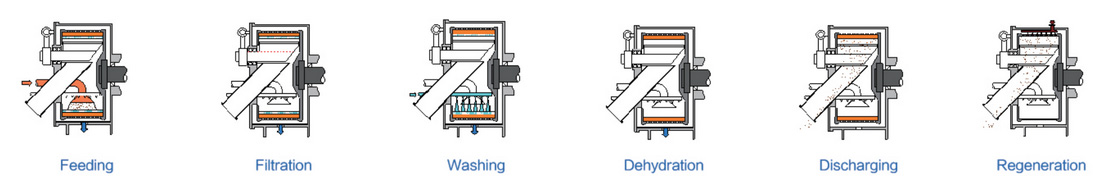

Working process

Automatic Horizontal Scraper Centrifuge peeler centrifuge Horizontal Centrifuge parameter

| Item/Type | GK/GKH800-N | GK/GKH1050-N | GK/GKH1250-N | GK/GKH1600-N |

|---|---|---|---|---|

| Drum diameter(mm) | 800 | 1050 | 1250 | 1600 |

| Drum length (mm) | 450 | 500 | 600 | 1000 |

| Drum volume (L) | 100 | 165 | 355 | 830 |

| Loading capacity (Kg) | 150 | 290 | 500 | 1050 |

| Drum speed (r/min) | 1550 | 1350 | 1200 | 950 |

| Maximum separation factor | 1070 | 1020 | 1006 | 799 |

| Motor power (Kw) | 30 | 45 | 55 | 90 |

| Size (mm) | 2030*1960*1530 | 2430*1980*1800 | 2685*2300*1900 | 4050*2745*2295 |

| Weight (Kg) | 5500 | 7900 | 10500 | 16550 |

LWL Horizontal screen worm centrifuges

The LWL screen worm centrifuge is a commonly utilized tool in various industries including chemistry, food processing, salt extraction, mining, and pharmacy. With its unique separation principle and structural features, it is most effective for materials with large particle size and excludes the need for precise particle crushing. As such, it is necessary to perform a thorough analysis and conduct relevant tests to assess its suitability and separation capabilities.

Technical Parameter

| Model | Bowl diameter (mm) | Bowl speed (r/min) | G-force (R/G) | Capacity (M³/H) | Mainmotor (Kw) | Weight (KGS) | Overall dimensions (L*W*H) |

|---|---|---|---|---|---|---|---|

| LWL200 | 200 | 4000 | 1790 | 0.5-1.5 | 3 | 550 | 1120*1020*800 |

| LWL 250 | 250 | 3500 | 1714 | 1.0-3.5 | 4 | 600 | 1120*1050*850 |

| LWL 320 | 320 | 2630 | 1240 | 0.5-2.5 | 7.5 | 700 | 1350*1050*1000 |

| LWL 350 | 350 | 3000 | 1770 | 1月3日 | 11 | 1000 | 1400*1250*1150 |

| LWL 450 | 450 | 2500 | 1580 | 2月5日 | 22 | 1500 | 1600*1400*1300 |

| LWL 530 | 530 | 2000 | 1190 | 3月10日 | 30 | 2000 | 1700*1450*1400 |

| LWL 630 | 630 | 1800 | 1140 | 5月15日 | 37 | 2500 | 2000*1440*1740 |

| LWL 800 | 800 | 1500 | 1006 | 8月30日 | 55 | 3700 | 2750*1750*2000 |

| LWL 1000 | 1000 | 900 | 450 | 10-50 | 75 | 6200 | 3200*2155*2280 |

Salt separation Applications

The HR series industrial centrifuge utilizes a two-stage piston pusher design and operates continuously as a filter-type centrifuge. It is capable of completing all operations – including feeding, separation, washing, drying, and unloading – at full speed. This centrifuge is suitable for separating crystalline or short fibrous concentrated suspensions and is widely used in industries such as chemical, pharmaceutical, light, and food. It is especially effective at separating solid phase materials with a particle size greater than 0.08mm and a concentration of more than 40% of contained crystals or fibrous solids for dehydration and solid-liquid separation.

The offered range of Applied Materials includes sodium chloride, ammonium chloride, potassium chloride, sodium sulfate, ammonium sulfate, potassium sulfate, urea, potassium carbonate, PVC, phosphate, nitrocellulose, cellulose acetate, and other materials.

Product drawings

Main configuration and parameter

| Model | HR300 | HR400 | HR500 | HR630 | HR 800 |

|---|---|---|---|---|---|

| Bowl inside diameter(mm) | 218/262 | 337/400 | 438/500 | 560/630 | 720/800 |

| Bowl length(mm) | 115/115 | 145/155 | 180/180 | 240/240 | 300/300 |

| Bowl rotation speed(r/min) | 2200 (Determined according to the use requirements) | 1500-2500 (Determined according to the use requirements) | 1200-2000 (Determined according to the use requirements) | 1000-1800 (Determined according to the use requirements) | 800-1600 (Determined according to the use requirements) |

| Separation factor | 710 | 573-1083 | 402-1120 | 350-1142 | 268-1145 |

| Pushing stroke | 30-80 time/min | 30-80 time/min | 30-80 time/min | 30-80 time/min | 30-80 time/min |

| Feeding capacity per hour | 1-3t/h | 1-8t/h | 5-15t/h | 8-25t/h | 25-65t/h |

| Main motor power(kw) | 5.5KW | 11KW | 45KW | 55KW | 55-75KW |

| Auxiliary motor power | 3KW | 5.5 KW | 22KW | 30KW | 37KW |

| Outline dimension(mm) | 1550*800*710 | 2460*1286*1180mm | 3600*1420 *2078 MM | 3690*1600*1265 MM | 3700*1800*1450MM |

| Machine weight (kg) | 1250kg | 2480kg | 3500kg | 4100kg | 7000kg |

Salt Machinery

The Allcentrifuges salt centrifuge is widely recognized for its exceptional dependability and tested consistency. Our mechanical and hydraulic salt centrifuges are designed to sustain continuous operation even in harsh environments, such as salt processing.

Our team of engineering experts specializes in tailored solutions for salt projects and equipment, meeting the unique needs of each customer.

Have Any Questions?